4.0T BOOST LEAK TESTER KIT - TEST UP TO 30 PSI & RESTORE LOST POWER!

Turbo Boost Leak TestersGet your boost back and get Full Performance From Your Turbos!

This boost leak tester kit is designed to fit over the two inlet pipes of your turbo charger and allows you to pressurize the whole charge system with compressed air upto 30 PSI while the vehicle is off, simulating normal boost conditions. Both turbo inlet pipes will have a tester installed to seal the charge sytsem. It is require to cap off the lines attached at the turbo intake pipe to avoid the PCV and crank case pressurization. The proper sized caps and plug are provided in this kit.

The best turbos the best fueling components can all be installed and if there are leaks in the charge pipes, the engine will not perform. Boost leaks will degrade engine performance in numerous ways including incorrect fueling where air fuel ratios are always chasing the incorrect amount of air, spark will we way off and additional heat will be introduced into the engine due to the turbos spinning way off their efficiency range aka spinning way too fast and blowing hot air.

This is an important tool every turbo car owner needs in their arsenal of tools. It will keep the turbos healthy by eliminating leaks in the boost path and not allowing them to over speed compensating for a boost leak. This will eventually lead to bearing wear and shaft play.

Boost leak testing is a must if:

- The vehicle is tuned (DS1 or APR stage I, II, III) especially since the boost levels are elevated and any leaks put an enormous load on the turbos to compensate for the leak.

- You are replacing any components in the intake tract such as charge hoses, intercooler, manifold, vac lines, injectors…etc.

- You are going to the track and want the peace of mind that the turbo wont over-work or risk blowing any hoses off that are loose!

Application & Fitment: (Choose the size you need in the options)

2.25" Stock Inlets:

Audi S6 S7 (C7), A8 (D4) 4.0T

2.5" Stock or Aftermarket Inlets:

Audi RS6, RS7 (C7), S8 (D4) 4.0T

Any 2.5" Inlets, SRM, ECS, etc

3" Aftermarket Inlets:

Audi S8 (D4) 4.0T with 3" inlets

Any 3" Inlets, SRM, aftermaket

Included Parts:

-

(2) 2” billet end caps with tire schrader & compressor fitting and 30 PSI boost gauges

-

(2) silicone couplers

-

T-Bolt Clamps

-

(2) Rubber Caps and 1" Plug

- (2) Inlet o-ring seals (for SRM inlets)

Basic steps to test:

- Install the testers on the inlets and clamp down

- Install the rubber caps and plug

-

1” Aluminum Plug:

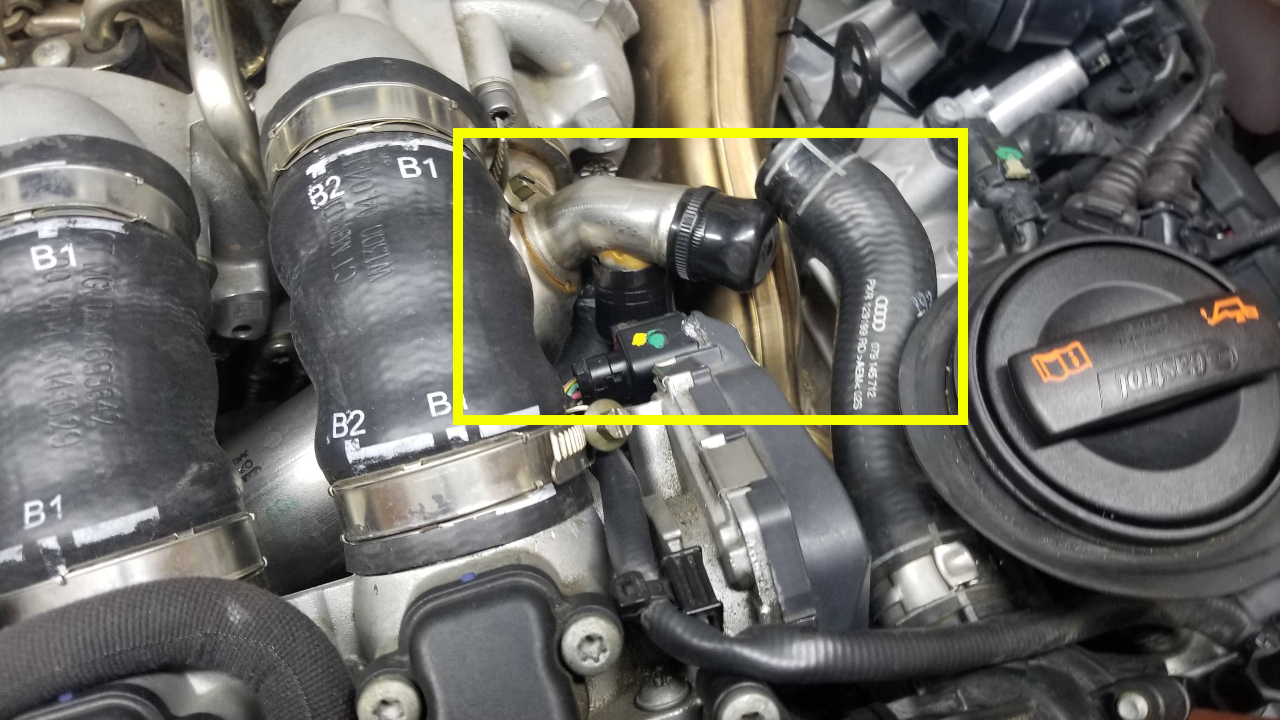

This installs on the rubber j-hose at the passenger side blow-off relief valve connection. Remove the j-hose from the blow off valve and slide the 1” aluminum plug into the J-hose. This blocks test air pressure from entering into the blow-off relief valve from the return side. Benefit of this is you will have the blow-off valve return lines disconnected and you can listen for leaks in the blow-off valve assembly

**Fun Mod: you can leave the billet plug in place and blow off or vent to atmosphere. The engine runs on speed density without a MAF sensor so it can vent to atmosphere not needing to meter the air.

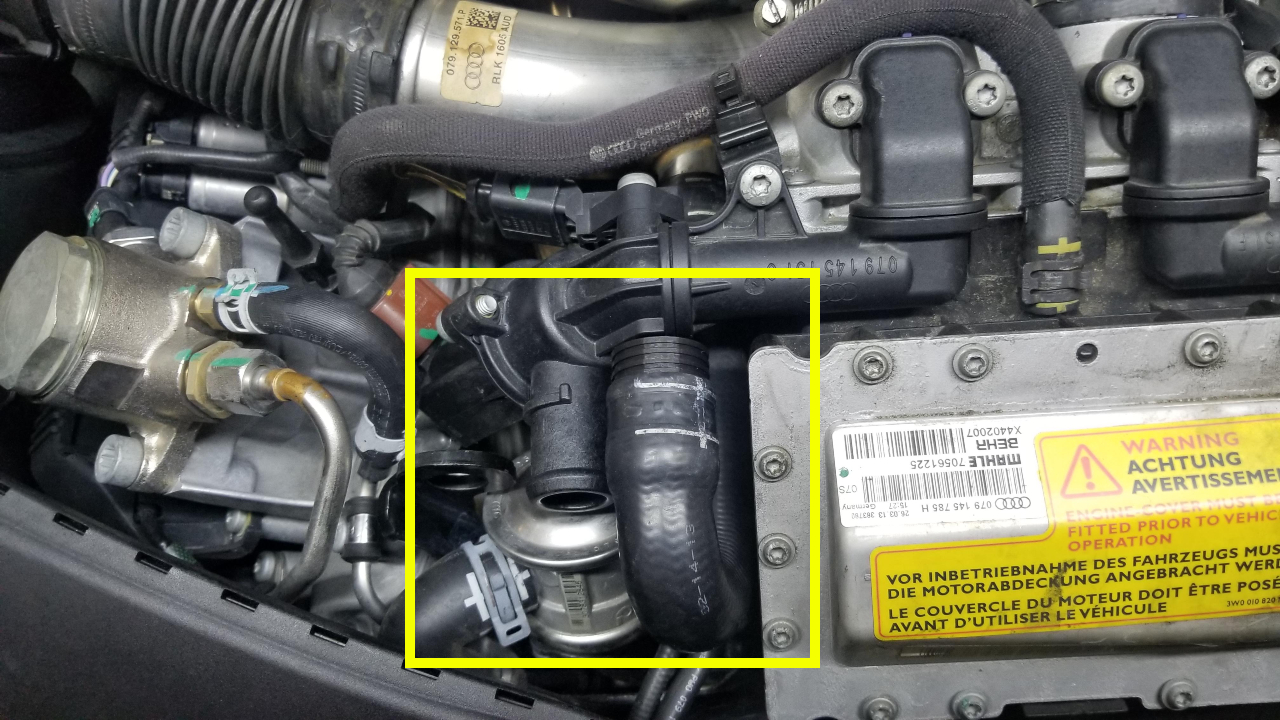

These 2 caps install on the drivers side turbo intake pipe right near the turbo. These caps block the test air pressure from entering into the PCV, Air/Oil Separator system and the drivers side blow-off relief valve return. If the PCV line is not blocked you will direct pressure into the air oil separator system and this will not allow only the charge pipes to be pressurized.

-

-

With the tester connected to the metal intake pipes, pressurize the system with 5 PSI using the tire schrader valve fitting (if using the air fitting provided regulate down your air compressor outlet). Listen for obvious leaks.

-

Fix the first leaks if any found - retest with the same pressure. If there are no more audible leaks then move up to a higher pressure, 10 PSI, then 15 PSI and recommended to test up to 25 PSI.

-

Bleed-down check: Once you have fixed all the audible leaks, fill the system with 20 PSI. With the air trapped in the syste watch the bleed down rate of the system. The system should hold pressure well and a bleed down with a rate of 1 PSI / second which is normal. Bleed down is inevitable since a minimal amount air is lost into the engine and makes its way into the crankcase.

-

If the system is bleeding much faster than 1 PSI/second and there are no audible leaks, there may be a pcv check valve leaking into the crankcase. They will need to be inspected, or air oil separator replaced.

*One major check valve is located between the bottom of the intercooler housing and air oil separator. This block boost from entering the pcv system when making boost.

*Another check valve is located at the fuel purge line. Follow and inspect the rubber hose from the top of the intercooler housing.